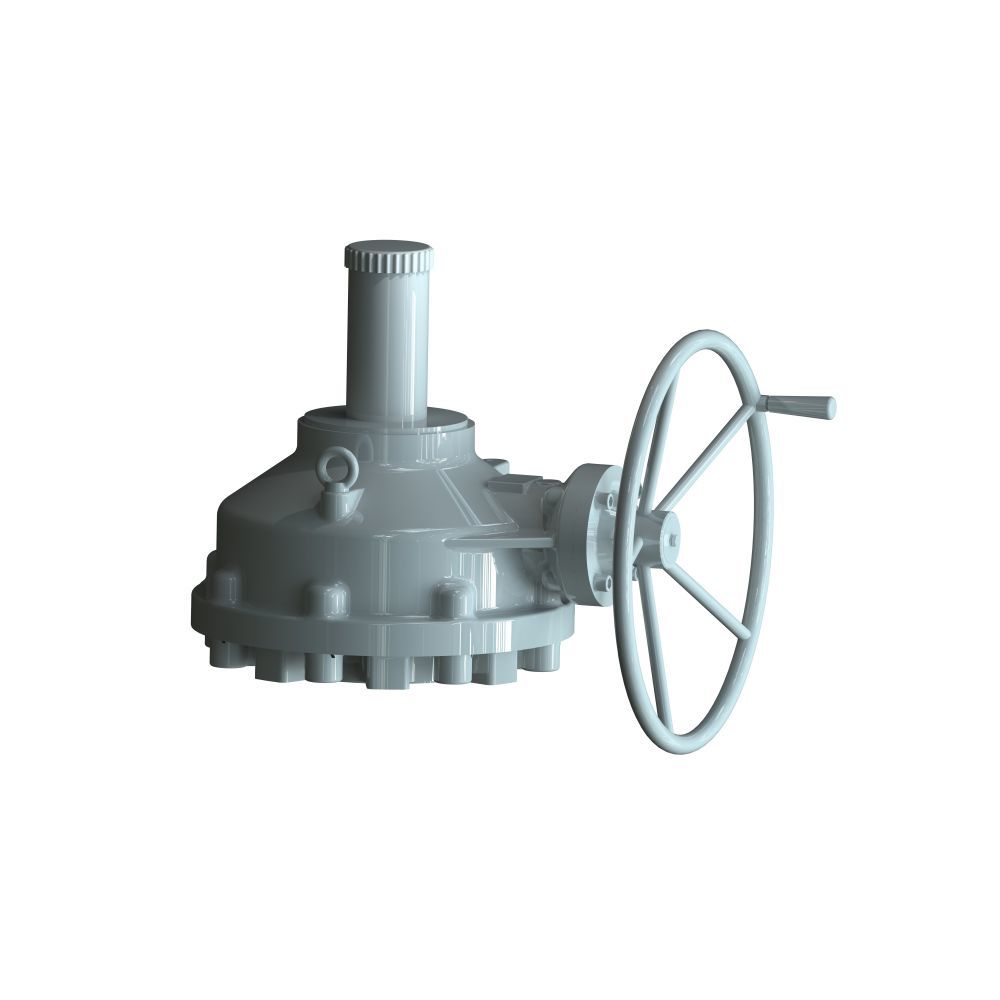

RK&2CK SERIES BEVELGEAR BOX

Keywords:

RK&2CK SERIES BEVELGEAR BOX

Email:

The rotary valve actuator is an essential and indispensable component in the industrial sector, widely used in various fluid control systems. Its primary function is to precisely control the opening and closing of valves via the actuator, enabling seamless fluid flow control as well as fine-tuned flow regulation. This article will provide a detailed overview of the technical features, operational principles, and practical applications of rotary valve actuators.

Product Description

Type |  | Technical Parameters | Basa Part | Extermal at | Handwreel | ||||||||||||||||||||||||||||||

Standard flangeacc.IS05211 | Optional Mountingacc.IS05211 | Ratio | Input Nm | Rating Output Nm | M.A.+10% | Max.Bore | Max. | Weight | D1 | P.C.D | D3 | H0 | H1 | H₂ | H3 | L2 | PD | Key | |||||||||||||||||

D2 | N-H-DP | M | |||||||||||||||||||||||||||||||||

A | RK03 | F12 | F10 | 4:1 | 105 | 350 | 3.4 | 40 | 93 | 15 |

| 25 | 4-M12-18 | 150 | 3 | 53 | 68 | 109 | 209 | 21 | 6 | 300 | |||||||||||||

RK05 | F14 | F12 | 4:1 | 165 | 550 | 3.4 | 52 | 127 | 21 | 100 | 140 | 4-M16-24 | 175 | 3 | 65 | 78 | 125 | 237 | 26 | 8 | 400 | ||||||||||||||

RK1 | F16 | F14 | 4:1 | 265 | 900 | 3.4 | 60 | 141 | 29 | 130 | 165 | 4-M20-30 | 210 | 4 | 73 | 91 | 138 | 247 | 28 | 8 | 500 | ||||||||||||||

2CK2 | F20 | F16 | 4.2:1 | 335 | 1200 | 3.6 | 65 | 190 | 41 | 140 | 20 | 5e-M16-2 | 4250 | 4 | 77 | 81 | 140 | 269 | 32 | 10 | 550 | ||||||||||||||

2CK3 | F25 | F16 | 4.1:1 | 575 | 2000 | 3.5 | 75 | 268 | 54 | 200 | 254 | 8-M16-24 | 300 | 4 | 86 | 88 | 152 | 310 | 32 | 10 | 600 | ||||||||||||||

2CK5 | F30 | F25 | 5.2:1 | 640 | 2800 | 4.4 | 90 | 308 | 88 | 230 | 29B | B-M20-30 | 350 | 4 | 102 | 108 | 181 | 380 | 32 | 10 | 700 | ||||||||||||||

2CK8 | F35 | F30 | 5.6:1 | 730 | 3500 | 4.8 | 110 | 377 | 160 | 260 | 356 | 8-M30-45 | 420 | 5 | 132 | 141 | 238 | 419 | 38 | 10 | 800 | ||||||||||||||

2CK10 | F40 | F35 | 6.3:1 | 840 | 4500 | 5.4 | 130 | 427 | 215 | 300 | 406 | B-M36-50 | 475 | 6 | 138 | 168 | 270 | 444 | 38 | 10 | 800 | ||||||||||||||

B | 2CK2-1 | F20 | F16 | 13.6: | 145 | 1400 | 9.8 | 65 | 190 | 82 | 140 | 205 | BM16-24 | 250 | 4 | 77 | 81 | 140 | 378 | 28 | 8 | 500 | |||||||||||||

18.8: | 105 | 13.5 | |||||||||||||||||||||||||||||||||

2CK3-1 | F25 | F16 | 18:1 | 195 | 2500 | 13 | 75 | 268 | 78 | 200 | 254 | 8-M16-24 | 300 | 4 | 86 | 88 | 152 | 402 | 28 | 8 | 550 | ||||||||||||||

24.6: | 145 | 17.7 | |||||||||||||||||||||||||||||||||

2CK5-1S | F30 | F26 | 23:1 | 245 | 4000 | 16.6 | 90 | 308 | 115 | 230 | 298 | BM20-30 | 350 | 4 | 02 | 108 | 181 | 489 | 28 | 8 | 800 | ||||||||||||||

31.2:1 | 180 | 22.5 | |||||||||||||||||||||||||||||||||

2CK-13 | F35 | F30 | 3.9: | 220 | 6000 | 27.3 | 110 | 377 | 205 | 260 | 356 | 8N30-45 | 420 | 5 | 32 | 41 | 238 | 544 | 38 | 10 | 700 | ||||||||||||||

50.4:1 | 170 | 36 | |||||||||||||||||||||||||||||||||

2CK10-1S | F40 | F35 | 42.8:1 | 290 | 9000 | 31 | 130 | 427 | 250 | 300 | 406 | BM98-50 | 475 | 6 | 138 | 163 | 270 | 570 | 38 | 10 | 700 | ||||||||||||||

56.7:1 | 220 | 41 | |||||||||||||||||||||||||||||||||

Rotary Valve Actuator: Technical Analysis and Application Overview

The rotary valve actuator is an essential and indispensable component in the industrial sector, widely used in various fluid control systems. Its primary function is to precisely control the opening and closing of valves via the actuator, enabling seamless fluid flow control as well as fine-tuned flow regulation. This article will provide a detailed overview of the technical features, operational principles, and practical applications of rotary valve actuators.

I. Technical Features

The rotary valve actuator boasts several key technical features, including high-precision control, highly efficient operation, and exceptional safety and reliability. Among these, high-precision control stands out as one of its core attributes, enabling accurate valve opening and closing to maintain stable operation of the fluid system. Additionally, the device incorporates advanced transmission technology, ensuring efficient performance while significantly reducing energy consumption. Meanwhile, its robust safety and reliability features have made it widely adopted, effectively mitigating potential hazards such as leaks.

2. Operating Principle

The working principle of the rotary valve actuator relies primarily on the coordinated operation of components such as the electric motor, gearbox, and transmission mechanism. When the motor starts, the gearbox reduces the rotational speed while simultaneously increasing torque. This mechanical power is then transmitted via the transmission system to the valve, enabling it to open and close. Throughout this process, sensors continuously monitor the valve's position and operational status, allowing the control system to maintain precise regulation.

3. Application Status

Rotary valve actuators are widely used in industrial sectors such as oil, chemical, power, and metallurgy. In the oil and chemical industries, these devices control a variety of fluid media, including gases, liquids, and steam. In the power industry, rotary valve actuators manage fluid systems in equipment like boilers and generator sets. Additionally, they find extensive applications in other industries, including metallurgy and water treatment.

IV. Conclusion

Overall, rotary valve actuators are indispensable and critical components in modern industrial applications. Their key features—such as high-precision control, highly efficient operation, and exceptional safety and reliability—have enabled these devices to be widely adopted across various fluid control systems. As industrial technology continues to advance, rotary valve actuators will undergo continuous innovation and upgrades, further contributing to the growth and evolution of the industrial sector.

Product Inquiry

Related Products

Multi-line text content element

After binding data, rich text content can parse HTML language content.

Multi-line text content element

After binding data, rich text content can parse HTML language content.

Multi-line text content element

After binding data, rich text content can parse HTML language content.

Address: NO.7A BULIDING, ZHUAO IND.ZONE,OUBEI STREET, YONGJIA, 325105,WENZHOU,ZHEJIANG CHINA

Mobile phone:86-15868793566

Phone:86-577-57775050

Fax: 86-577-57779292

Email:boho@china-boho.com